The integration of hydrogel dispensation technology into disposable medical electrodes has brought significant advancements, revolutionizing patient experience and diagnostic accuracy. Dispensable hydrogel and sheet hydrogel are two different forms of hydrogel used in medical electrodes, each with its own advantages and use cases. In this article, we explore the numerous benefits of dispensable hydrogel, highlighting its impact on patient comfort, signal quality, and overall healthcare outcomes.

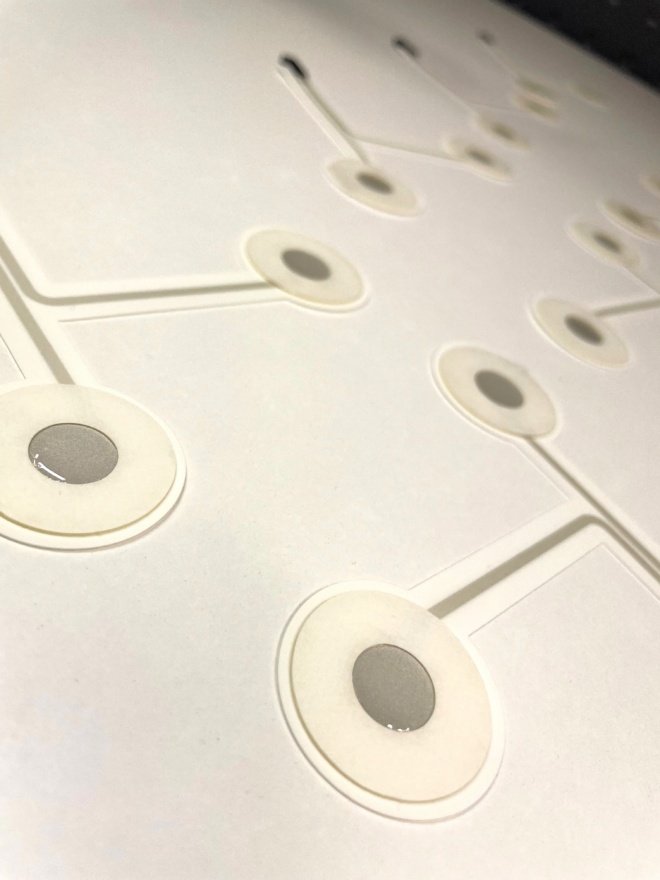

Customizable Application: Dispensable hydrogel allows for precise and customizable application. It can be dispensed in various patterns and shapes to suit the specific electrode design and placement requirements.

Customizable Application: Dispensable hydrogel allows for precise and customizable application. It can be dispensed in various patterns and shapes to suit the specific electrode design and placement requirements.

Complex Electrode Designs: Dispensable hydrogel is particularly advantageous when designing complex or irregularly shaped electrodes. It can be applied directly to the desired area, ensuring optimal contact and adherence.

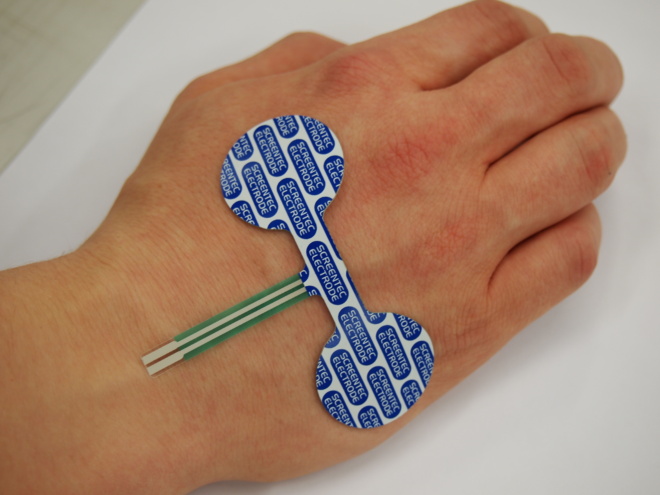

Conformity and Adhesion: Dispensable hydrogel provides excellent conformability to the skin’s contours, ensuring consistent and reliable electrode-skin contact. This is especially beneficial for electrodes placed on challenging anatomical areas. Adhesion can be increased or decreased, depending on the application.

Reduced Waste: Dispensing hydrogel directly onto the electrode minimizes waste compared to sheet hydrogel, which requires trimming and discarding excess material.

Uniform Thickness: The dispensing process allows for better control over the hydrogel’s thickness, ensuring uniformity across the electrode and enhancing electrical conductivity.

Reduced Air Trapping: Dispensing hydrogel can help reduce the likelihood of air trapping between the electrode and the skin, which can lead to signal interference and unreliable readings.

Ease of Use: Dispensable hydrogel simplifies the manufacturing process as it eliminates the need to align and attach pre-cut sheets of hydrogel to electrodes.

Hygienic and User-Friendly Design: Disposable medical electrodes are always designed with utmost hygiene and user-friendliness in mind. The hydrogel layer acts as a conformable barrier, preventing direct contact between the patient’s skin and the sensor. This reduces the risk of irritation. Furthermore, well designed electrode supports ease of application and removal – simplifying the electrode placement process, saving valuable time for healthcare professionals and ensuring a hassle-free experience for patients.

Optimized Conductivity: Dispensable hydrogel can be formulated to optimize electrical conductivity, according to application, ensuring accurate and consistent signal transmission between the electrode and the skin. This improved signal quality enables healthcare professionals to obtain clear and reliable readings, leading to more accurate diagnoses and treatment decisions, even in long-term monitoring applications up to three weeks.

Optimized Conductivity: Dispensable hydrogel can be formulated to optimize electrical conductivity, according to application, ensuring accurate and consistent signal transmission between the electrode and the skin. This improved signal quality enables healthcare professionals to obtain clear and reliable readings, leading to more accurate diagnoses and treatment decisions, even in long-term monitoring applications up to three weeks.

Cost-Effectiveness: While the initial investment in dispensing equipment may be higher, over time, dispensable hydrogel can lead to cost savings due to reduced waste and increased efficiency in the manufacturing process.

It’s important to note that the choice between dispensable hydrogel and sheet hydrogel depends on various factors, including the electrode design, intended application, wear time, cost considerations, and specific requirements of the medical device. Screentec uses either type of hydrogel based on the product’s unique needs and performance goals.

At Screentec, we are using an automated production equipment for sheet handling and dispensation of hydrogel. Transparent films are brought into the device as sheets in a transport unit, from where they are automatically transferred to the suction table, one film at a time, for liquid dispensation. The advantages of automated hydrogel dispensation are pace, repeatability and much larger volumes compared to manual dispensation.

Hydrogel dispensation is yet another one of Screentec’s in-house capabilities. Vertical integration brings efficiencies to our manufacturing process, lowering the reliance on external parties, as well as reducing the cost and time it takes to move from prototype to mass production. As your vertically integrated partner, Screentec provides manufacturing services in the fields of user interfaces, disposable medical electrodes, wearable diagnostics and electrochemical sensors. We also offer productization consultation services in order to help our customers find the most efficient way to prepare their prototypes and concept products for market production.

Hydrogel dispensation has revolutionized the field of disposable medical electrodes, significantly improving patient comfort, signal quality, and overall healthcare outcomes. The integration of hydrogel dispensation in medical electrodes demonstrates a commitment to providing accurate diagnoses, reducing patient discomfort and streamlining medical procedures. As this innovative technology continues to evolve, we can anticipate even more advancements that will shape the future of healthcare.

In a world where precision meets innovation, Screentec stands at the forefront of hydrogel technology. With a firm grasp on vertical integration, we pave the way for efficiency, cost-effectiveness and rapid progress. As a dedicated partner, we don’t just manufacture, we elevate healthcare experiences – one hydrogel drop at a time.